The laser cutter is the “cool factor” tool of any makerspace. It is the most useful as it can make very precise cuts or designs with (1200 dpi and cut the width of a hair) a wide range of materials, while producing less waste than a CNC mill.

NOTE: I do not recommend this as your first or even second tool. A maker needs to spend lots of time on an FDM style 3D printer (typical kind) before spending the money on a laser. A CNC mill is also a great tool to get started with subtractive making before this large investment.

Contents:

Starter Supplies

Supplies Needed ongoing

Three Example Engravers

Fun Projects

My fav items to cut:

General Starter Supplies:

Generally you will want to test your designs on cardboard (+/- $1 for 12”x24”), then work with your final medium like ⅛” birch ($3 for 12”x24”) or cast sheet acrylic ($10-20 for 12”x24”).

The ATX Hackerspace out of Austin gave an incredible list of laser cuttable items with MSDS information and lots of notes.

I have started looking for cabinetry shops like Wurth Group here in the south who sell 5ft x 5ft sheets of cabinet grade 1/8” Baltic Birch for under $20. That equates to less than $1 for the same sheet listed above.

Check ebay and amazon for sales of 24x24 sheets. Sibe Automation will run sales for big sheets where you are pretty much only paying shipping.

As this is such a big investment, many options are comparable. Much of the price difference goes to bed size and cut speed. If you have a lower wattage laser, you have to move it slower to cut deeper. Think of it like a magnifying glass to burn leaves. If it is hotter, it burns quicker and deeper.

-Lower-end systems need water cooling (glass tube DC CO2 lasers like Full Spectrum) and high-end systems can be cooled with moving air across fins surrounding the tube (RF DC CO2 lasers like Universal). All will need fume extraction or exhaust fans to remove the smoke and waste, and they are normally included in the packages.

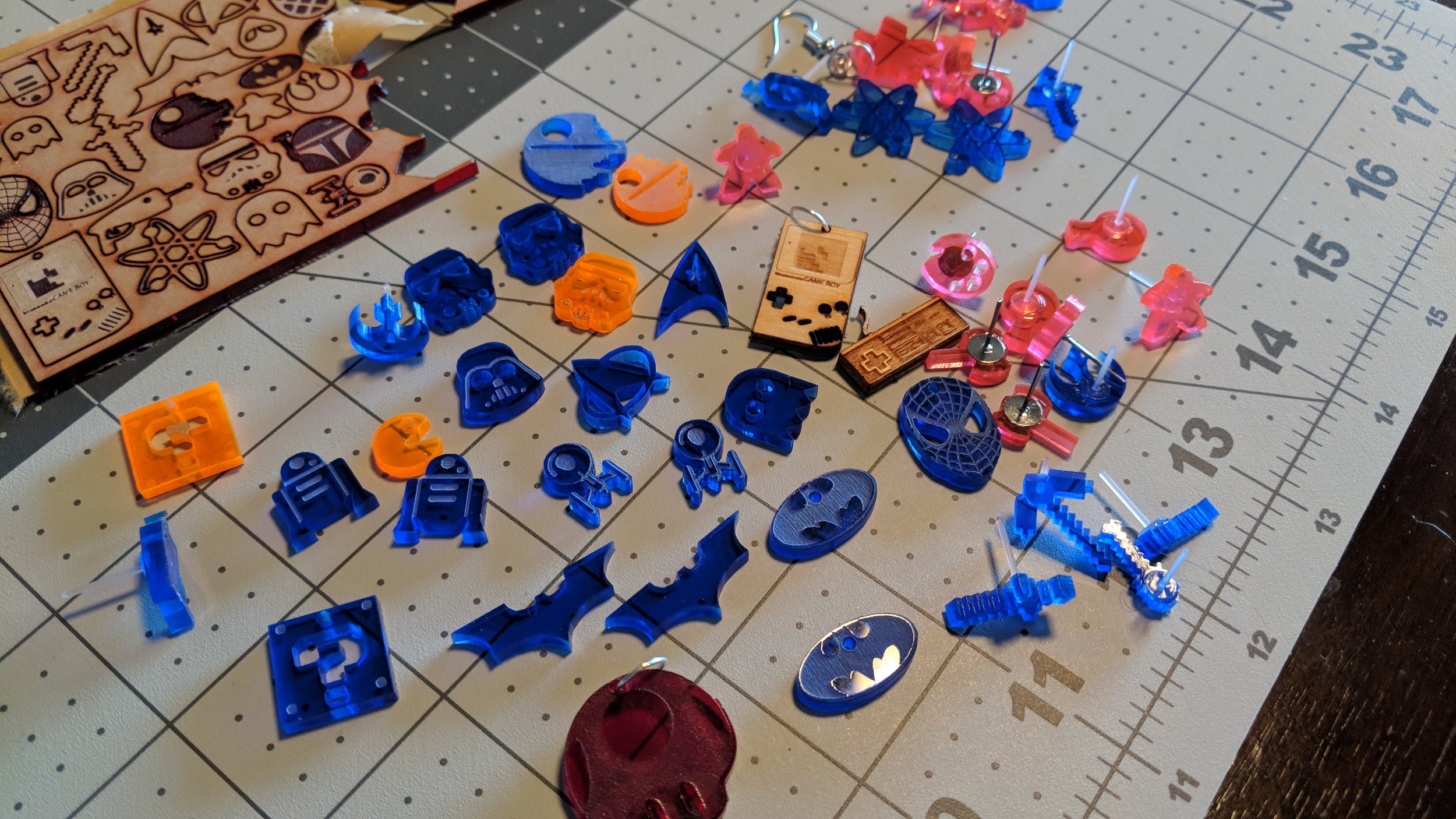

TinkerIT Laser Projects

A Few Reviews

There are many more options out there, and I will continue to add them to the list. These three are examples from the three main manufacturers for makerspace-style lasers. You can buy larger ones and cheaper ones, but these laser cutters have been tested and are in use in dozens of maker spaces and STEM classrooms.

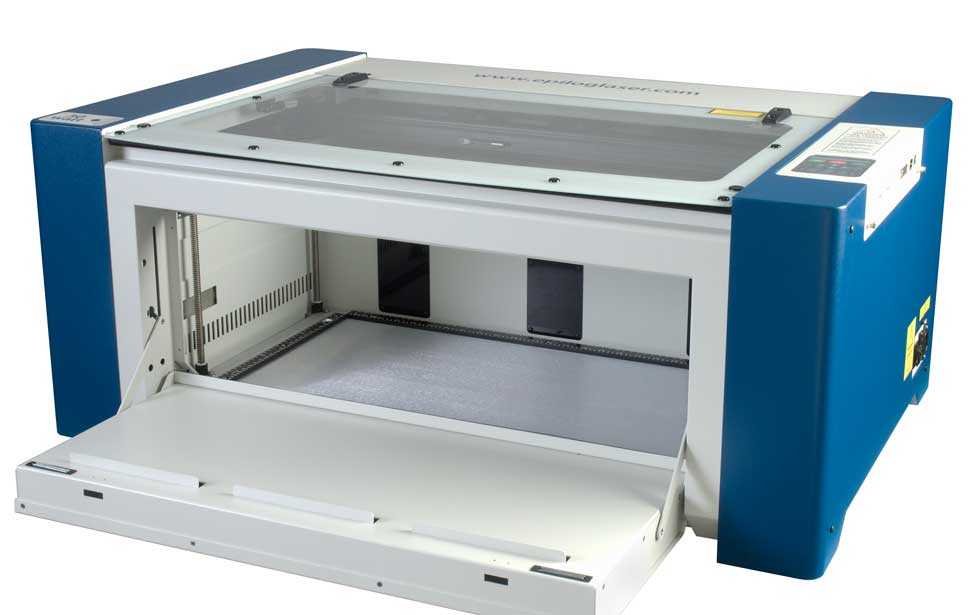

The Gold Option: Epilog Zing 24

24”x12” cut area with 60-watt RF CO2 sealed laser - Optional 16x12 bed and 20-60 watt options

Pros: Professional Machine, incredibly easy software, much faster cuts, Z platform (the bed) lowers for large items to fit inside or underneath. Deeper cuts are possible with optional lenses. RF tubes are in professional cutters for longer life, better precision and recharged if needed, after thousands of hours.

This can be a wonderful second unit or replacement when the Silver or Bronze package item dies (after a few thousand hours of usage). Pretty much everything is automatic on it once it is set up. Lots of available tech support. Rugged designs meant to be used every day for small businesses. Printer drivers let you use any graphics software and hit print. This is becoming more common with laser cutter/engravers, and the big difference is how they read colors and grayscale.

Needed accessories:Ventilation system, vector (honeycomb) grid bed, and one lens

Optional accessories: Rotary attachment (to cut/engrave round objects like cups and glasses), 1.5”, 2”, 2.5”, 4”, 5” lenses. (Each lens cuts at a different depth. Shorter lenses needed for raster engraving, and long lenses for deeper cuts. 2” is normal/middle)

Complete, everything, turn-key package: $14,000 +/-

Initial package with only necessities: $10-12,000

There are lease options starting at $150/mo

Silver Package +:Full Spectrum P-Series 20x12 45 watt

(optional 24x16, 36x24, 48x36” cut beds and 20-120 watts DC glass tube CO2 laser which is not rechargeable)

Pros: Full Spectrum is the brand most makerspaces decide to use for their affordable price point. The software is constantly being updated. Side and front panels are removable to slide in long or wide items. Heavy-duty X-axis and Y-axis rails help keep “jelly bounce” down when going very fast on raster engraving. The P-series is Full Spectrum’s professional line and their answer to the Epilog Zing. It comes in at half the price of the Epilog competitor.

Cons: Glass tubes are not rechargeable and do not pulse as fast as RF or run daily like RF. They are fine for makerspaces, but not best for a sign shop. Needs water chiller.

Needed accessories: Ventilation/Air Filtration system, Water Cooler (glass tube DC lasers need water flow to cool. RF only needs air), 2” lens, up to 2-year warranty.

Optional accessories: 1.5, 2, 2.5, 5” lenses, bigger fume extractors, bigger water coolers, rotary attachment for round objects.

Suggested package to start: $7,545 Water chiller, 2” lens, small fume extractor and 2-year warranty. Still need delivery estimate.